The secret of maintenance methods for jet high-speed light edge machines! Jet high-speed edging machine is a shuttleless jet high-speed edging machine that uses jet airflow to pull weft yarn through the shed. The working principle of the jet high-speed edging machine is to use air as the weft insertion medium, and use the compressed airflow to generate frictional traction force on the weft yarn for traction. The weft yarn is carried through the shuttle mouth, and the weft insertion is achieved through the jet generated by the jet.

1、 Regular maintenance and upkeep of jet high-speed edging machine

1. Daily maintenance and handling of maintenance workers require daily maintenance of the electric oil pump, centralized oil supply, main motor heat dissipation parts, input shaft of the open cam box, electromagnetic brake, weft detector, scissors, twisted edge, edge support, and edge processing yarn of the jet high-speed trimming machine.

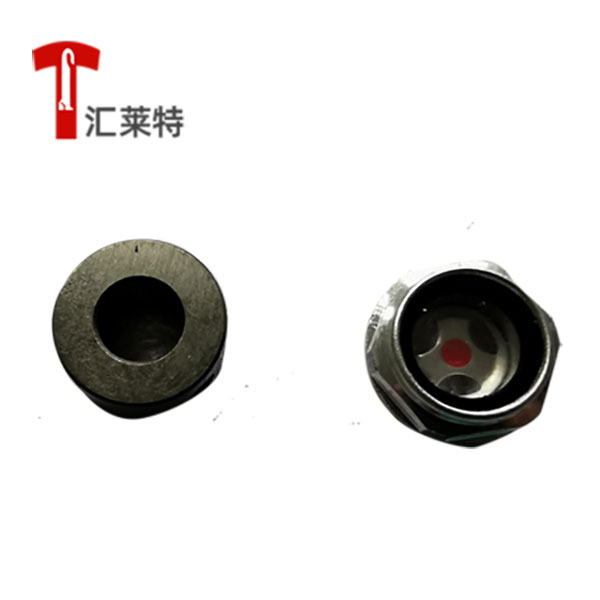

2. During the maintenance and handling of the machine, check whether the edge support ring rotates flexibly, whether it is worn, whether there are flying flowers accumulated, whether the spacing between the stop pin and the main drum is 0.5 mm, whether there is air leakage in the air pipe, whether there is oil leakage in the centralized oil supply, whether there is damage or bending in the oil pipe, whether there are flying flowers accumulated inside the control box, confirm whether the height error of the comprehensive frame is within 2mm, whether the exhaust pipe of the air filter is unobstructed, whether there are flying flowers on the small gear of the warp shaft, whether there are yarn heads on the bevel gear shaft of the opening device, whether the sieve holes on the oil filter are blocked, whether there are yarn heads rolled up on the warp and loosening shafts, whether there is damage to the insulation edge sleeve of the wire, and whether the gap of the brake is correct. Add oil to the nozzle area, add oil to the tooth surface and chain of the open gear, and check for wear on the heald frame and its guide plate.

3. Half year maintenance and handling require checking whether the winding is clean, whether there are yarn marks and injuries on the main drum and sales drum, whether the inside of the yarn stop pin component is dirty, whether the opening steel wire rope is elongated or damaged, whether the return spring is damaged, and whether the bearing of the opening steel wire rope connection seat is worn. Whether the tension of each belt is appropriate, whether there is any damage, whether each sensor is working properly, whether the transmission gearbox, coiling gearbox, and feeding gearbox are replaced with lubricating oil, and whether the iron filings on the magnet of the open camshaft are removed. Whether the filter mesh is blocked, whether the steel reed is contaminated with dirt, whether the wind speed is normal, whether the wear of the U-shaped bushing of the pull-down hook is within 2mm, whether the main nozzle guide pipe is bent, whether the coiling roller chain is extended, whether the planetary gear tooth clearance is normal, whether the wear of the planetary tube seat bushing is within O.5mm, whether the wear of the planetary tube shaft is within 0.5mm, whether the wear of the planetary tube bushing is within O.5mm, and whether there are yarn marks on the auxiliary nozzle. Whether it is bent, whether the scissor device has oil, etc.

4. If the screws on the main nozzle support feet are loose during the one-year maintenance and handling, they need to be tightened again.

5. Two years of maintenance and handling, whether there is wear on the coiling roller, pressure roller, and rough rubber, whether the wear on the warp shaft is within 0.3mm, whether the performance of the buffer has decreased, whether there is wear on the nylon bushing and buffer guide pin column, whether the auxiliary nozzle is dirty, whether the yarn supply side scissor device can correctly cut the weft yarn, whether there is wear on the stop pin hole of the stop pin component, whether it is within 0.5mm, and whether the wear on the warp part of the coiling cloth roller is within 0.5mm.

6. Three years of maintenance and handling, whether the lubricating oil of the solenoid valve is insufficient and whether the coiling and rolling rolls can rotate flexibly.

7. The seven-year major overhaul includes the maintenance of various bearings, oil seals, gears, camshafts, bushings, stop pins, main motors, as well as related parts of the frame, opening, warp feeding, coiling, and weft storage.

Jet high-speed edging machine

2、 The contents and precautions to be taken for the preservation of various mechanisms after long-term use of jet high-speed edging machines

Main transmission part: After long-term use of the jet high-speed polishing machine, it is necessary to replace the crankshaft bearing seat oil seal of the driving part. Opening part: It is necessary to replace the cam opening arm bearings, steel wire ropes, return spring, and return arm bearings. Replace the synchronous toothed belt and clean the oil filter. Regularly clean the steel reeds of the high-speed jet edging machine. Replace the internal parts of the measuring and storage drum, replace the internal parts of the yarn stop pin, and clean the encoder. Main nozzle cleaning, filter cleaning, cleaning and repair of solenoid valves and pressure regulating valves, inspection and configuration of air pipes. Repair and replacement of servo motors, maintenance of buffers, and replacement of internal components. Check and replace the brake rollers, chains, tensioning wheels, adjustment pins, and maintenance and replacement of friction plates and discs of the jet high-speed edge polishing machine. Inspection and replacement of rough rubber. Check and replace the planetary gears, tube bearings, yarn guide arm shafts, and couplings. Check and replace the weft detection cable of the jet high-speed light edge machine.